Diebold刀柄符合DIN 69893-1 HSK-E32

Diebold專門設計了刀柄,用于加工鈦和氧化鋯材料。 Diebold HSC刀柄具有涂層,因此可防止粘附污垢或銹蝕。這使Diebold成為HSC加工的理想選擇,因為它要求高跳動精度和低不平衡程度。

Diebold CentroGrip?筒夾夾頭的錐度和內徑之間的跳動精度<1微米。

現在,客戶正在尋求具有小于1微米的徑向跳動的熱縮夾具。要實現這些精度并不容易,但Diebold的巧妙設施和制造技術訣竅Diebold能夠提供精度等級的刀架。

平衡質量:高性能刀柄的平衡質量變得越來越重要。如果所需的刀架在這些刀架設計的整個速度范圍內平衡到G0,1。

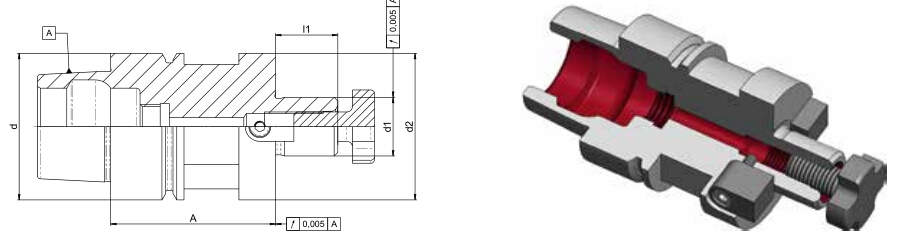

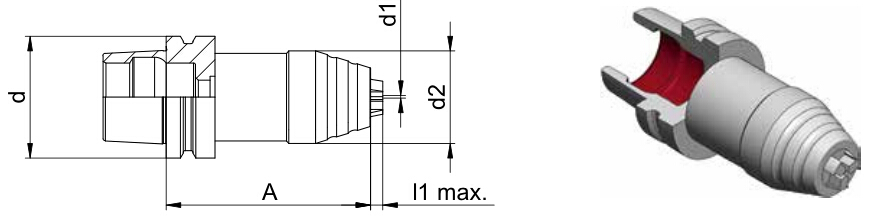

Diebold帶有固定傳動鍵銑刀柄

精確平衡G2.5 20,000轉

應用:卷取刀頭,鋸片等。

供貨范圍:切刀擰緊螺釘和傳動銷。

| Order-No. | HSK-E | d1 | d2 | l1max | A | rpm |

| 72.563.120.200 | 3225 | 16,0 | 40,0 | 17,0 | 45,0 | 32000 |

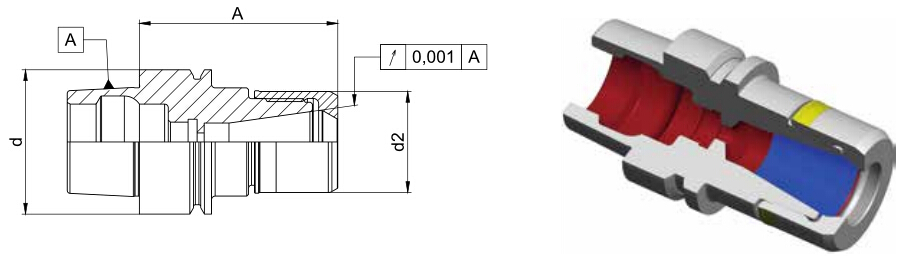

Diebold CentroGrip?高精度夾頭刀柄

應用:高精度夾緊帶圓柱柄的刀具。

交付:使用夾緊螺母和操作手冊。

備注:使用特殊CentroGrip?扳手擰緊。

| Order-No. | HSK-E | d1 | d2 | l1max | A | rpm |

| 72.563.485.100 | 32 | 16 | 60 | MR11 | Mini | 40000 |

| 72.563.485.200 | 24 | 55 | MR16 | Mini | 40000 |

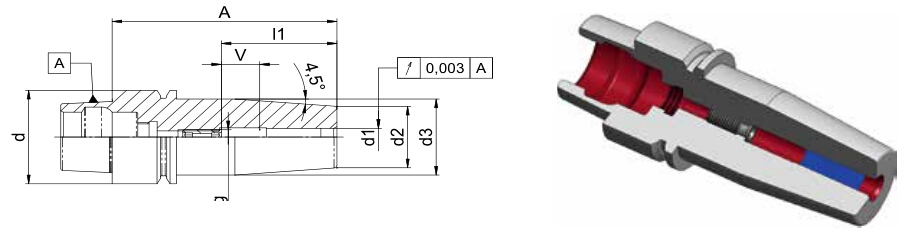

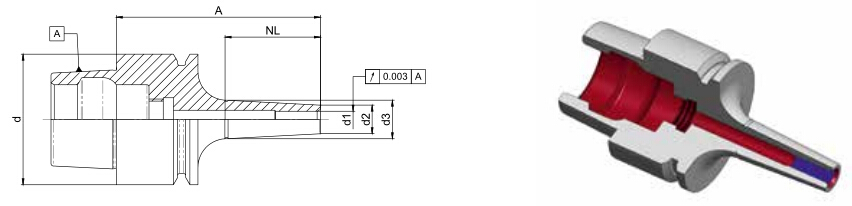

Diebold HSK Shrink Fit刀柄

應用:快速和安全地夾緊帶圓柱柄的刀具。 我們的卸壓孔易于操作(從?6mm開始)。 非常適合HPC和HSM等高RPM應用。

交貨:帶長度調節螺絲的收縮夾頭。

備注:您可以將可用的感應收縮裝置與Diebold Shrink Fit卡盤一起使用。 為了獲得佳的工藝可靠性和夾頭的長壽命,推薦使用ThermoGrip?收縮單元。

| Order-No. | HSK-E | d1 | d2 | d3 | l2 | A | g | HSS | V | rpm |

| 72.563.500.010 | 32 | 3,0 | 15,0 | 20,0 | 20,0 | 60,0 | M6 | - | 5 | 46000 |

| 72.563.500.040 | 4,0 | 15,0 | 20,0 | 20,0 | 60,0 | M6 | - | 5 | 46000 | |

| 72.563.500.070 | 5,0 | 15,0 | 20,0 | 25,0 | 60,0 | M6 | - | 5 | 46000 | |

| 72.563.500.100 | 6,0 | 21,0 | 26,0 | 36,0 | 70,0 | M5 | √ | 10 | 46000 | |

| 72.563.500.200 | 8,0 | 21,0 | 26,0 | 36,0 | 70,0 | M6 | √ | 10 | 46000 | |

| 72.563.500.300 | 10,0 | 24,0 | 29,0 | 42,0 | 70,0 | M8x1 | √ | 10 | 46000 | |

| 72.563.500.400 | 12,0 | 24,0 | 29,0 | 47,0 | 70,0 | M10x1 | √ | 10 | 46000 |

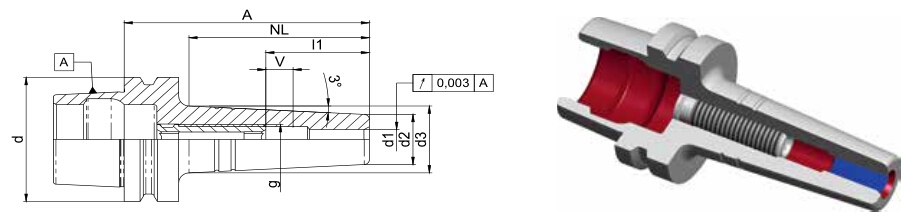

Diebold HSK ShrinkFit刀柄TSF Slim版本

精細平衡G2.5 25000 U /分鐘

應用:快速和安全地夾緊帶圓柱柄的刀具。 通過纖細的設計達到小的碰撞幾何。 深腔的理想選擇。

交貨:帶長度調節螺絲的收縮夾頭。

注釋:您可以將可用的感應收縮裝置與Diebold Shrink Fit卡盤一起使用。 為了獲得佳的工藝可靠性和夾頭的長壽命,我們推薦使用ThermoGrip?收縮單元。

| Order-No. | HSK-E | d1 | d2 | d3 | l1 | A | NL | g | HSS | V | rpm |

| 72.563.501.010 | 32 | 3,0 | 9,0 | 13,0 | 20,0 | 64,0 | 40,0 | M6 | - | 5 | 50000 |

| 72.563.501.012 | 3,0 | 9,0 | 16,0 | 20,0 | 94,0 | 70,0 | M6 | - | 5 | 50000 | |

| 72.563.501.040 | 4,0 | 10,0 | 14,0 | 20,0 | 64,0 | 40,0 | M6 | - | 5 | 50000 | |

| 72.563.501.042 | 4,0 | 10,0 | 17,0 | 20,0 | 94,0 | 70,0 | M6 | - | 5 | 50000 | |

| 72.563.501.100 | 6,0 | 12,0 | 17,0 | 36,0 | 74,0 | 50,0 | M5 | - | 5 | 50000 | |

| 72.563.501.150 | 6,0 | 12,0 | 20,0 | 36,0 | 104,0 | 80,0 | M5 | - | 5 | 50000 | |

| 72.563.501.200 | 8,0 | 14,0 | 19,0 | 36,0 | 74,0 | 50,0 | M6 | - | 5 | 48000 | |

| 72.563.501.250 | 8,0 | 14,0 | 22,0 | 36,0 | 104,0 | 80,0 | M6 | - | 5 | 48000 | |

| 72.563.501.300 | 10,0 | 16,0 | 21,0 | 42,0 | 78,0 | 55,0 | M8x1 | - | 5 | 48000 | |

| 72.563.501.350 | 10,0 | 16,0 | 22,0 | 42,0 | 104,0 | 80,0 | M8x1 | - | 5 | 48000 |

Diebold HSK ShrinkFit刀柄TUS超薄版本

建議收縮裝置:MS 502-P

精細平衡G2.5 25

| Order-No. | HSK-E | d1 | d2 | d3 | l1 | A | NL | g | HSS | rpm |

| 72.563.503.010 | 32 | 3,0 | 6,0 | 9,0 | 20,0 | 50,0 | 22,0 | - | - | 50000 |

| 72.563.503.040 | 4,0 | 7,0 | 10,0 | 20,0 | 50,0 | 23,0 | - | - | 50000 | |

| 72.563.503.100 | 6,0 | 9,0 | 12,0 | 36,0 | 50,0 | 24,0 | - | - | 50000 |

Diebold 微型鉆頭刀柄

精細平衡G2.5 25000 U /分鐘

同心度<0.03μm

| Order-No. | Taper | d1 | d2 | l1max | A | rpm |

| 72.563.533.015 | 32 | 0,2-1,5 | 19,0 | 2,5 | 50,0 | 38000 |

| 72.563.533.030 | 1,5-3,0 | 19,0 | 2,5 | 50,0 | 38000 |

上海浦東康意路551號2號樓2樓西

上海浦東康意路551號2號樓2樓西

021-50396508

021-50396508